Being adept in the use of a bandsaw involves more than having a simple knack for operating the machine.

Precise knowledge of its intricate details, including the throat and wheel diameter specifications, constitutes a crucial chunk of this understanding. Running the bandsaw may seem a straightforward affair, yet it assumes a strenuous task, especially when tracking down the ideal blade length.

Deep diving into the very tenet of this guide, this discourse provides a comprehensive interpretation of bandsaw specifications, the mathematical formulae behind blade length, and how all these are brought to bear in actual woodworking scenarios.

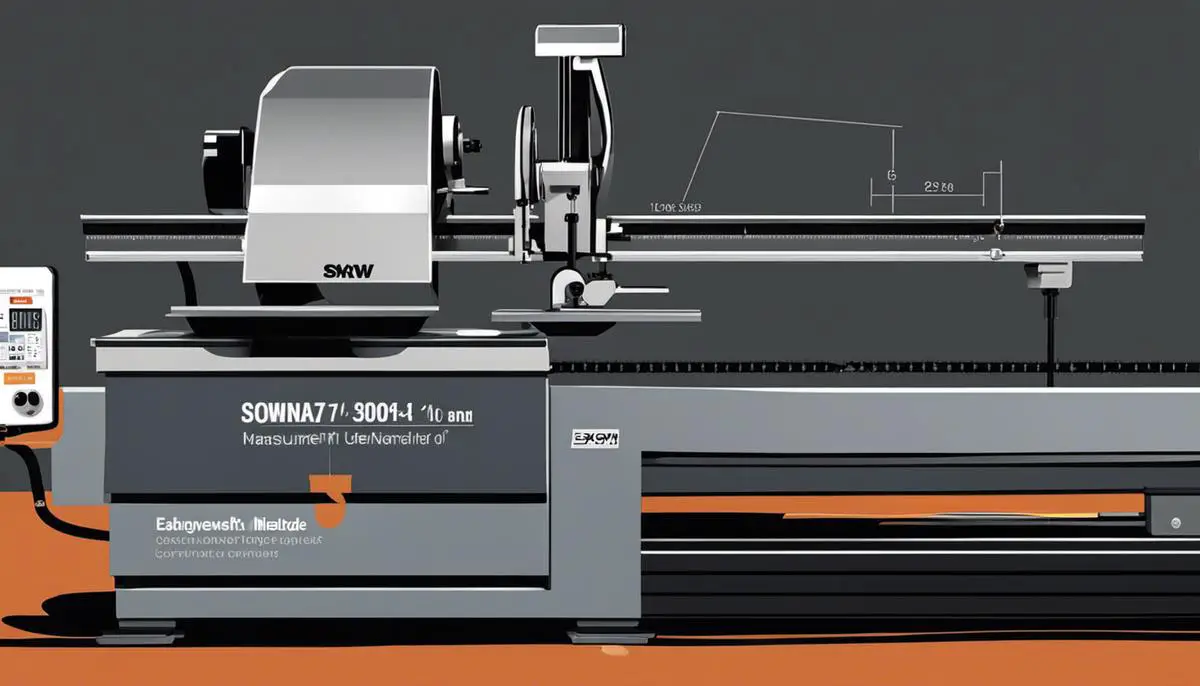

Bandsaw Blade Length Calculator Specifications

BandSaw Blade Length Calculator

Every hobbyist knows that the right tool can make all the difference in pursuing one’s passion. Today, we’re going to delve into the incredible world of bandsaws—a critical tool, a game-changer that has a distinct place in your woodwork projects.

Let’s explore the specific identifying specifications of bandsaws, enhancing your knowledge from the enthusiastic beginner to the veritable pro.

The Frame: A Key Structural Element

A bandsaw’s frame holds it together – literally. These frames come in a wide variety of materials, from hefty cast iron to lighter, yet incredibly tough, pyramid-style steel.

A critical virtue of the frame is its rigidity. Higher rigidity translates to superior cut precision. Let’s also not forget the importance of size. Smaller bench-top models are perfect for hobbyists, while larger floor-standing models are a must for serious woodworking.

Power & Speed: The Heart of Your Bandsaw

Like other power tools, understanding the motor’s power in bandsaws significantly affects its performance.

Their power can range between 0.5 to 1.5 HP for lighter tasks and upwards of 2 to 3 HP for heavy-duty ones. Motor speed, given in RPM (Revolutions Per Minute), can be regulated, allowing one to cut various materials at their optimal cutting speed.

Size & Capacity: Working with Diverse Materials

The size of the bandsaw is determined by the diameter of the wheels and, consequently, the length of the blade it can accommodate. A 14″ bandsaw, for instance, can support a blade approximately 93″ long.

Furthermore, the bandsaw’s cutting capacity (which includes throat and depth capacity) will determine the thickness, length, and width of the material you can work with.

Blades: Crafting Your Desired Outcome

The blade is undoubtedly a cardinal part of your bandsaw — it shapes your creativity. Understand that bigger doesn’t necessarily mean better when selecting a blade size.

Thin blades are ideal for intricate, detailed work, while broader blades work wonders for resawing and ripping lumber. Equally important is the TPI (Teeth Per Inch) ratio: fewer TPI results in faster, albeit rougher cuts, whereas more TPI provides slower, but smoother cuts.

Table: Your Work Station

The table is where the magic of crafting comes together. Made from cast iron or aluminum, it is a sturdy platform where materials are fed to the blade.

It must be flat, smooth, and allow for effortless material gliding. Precision tilted tables enable bevel cuts, opening up a variety of creative possibilities.

Safety Features: Prioritizing Your Well-being

Last but in no way least, bandsaws come with a multiple safety features—blade guides to keep the blade from deflecting, tension adjustment for securing the blade, and emergency stops are some of them.

A dust collection port ensures dust-free working conditions, adding to longevity and, most importantly, user safety.

So, there you have it! Bandsaws are indeed versatile and incredibly useful tools for any woodworking enthusiast, ranging from the beginner to the seasoned expert.

Understanding their identifying specifications clears the path to selecting the best bandsaw to support your crafting journey.

Here’s to creating, refining, and mastering your woodworking passion. After all, seeing a hunk of raw material transform into a piece of crafted beauty under the exact, steady pull of a bandsaw continues to be nothing short of magic!

The Mathematics Behind Blade Length

Let’s switch gears now and delve a little deeper into a topic that’s perhaps not as universally understood, but just as significant – blade length on a bandsaw.

Understanding how blade length is calculated can have a significant impact on both the efficiency and the safety of your bandsaw operation.

Put simply, the bandsaw blade length is dictated by the size of the bandsaw itself, specifically the distance from the two wheels on which the blade runs. These two wheels, often referred to as the bandsaw’s ‘wheel diameter’, are factors that directly influence blade length.

To calculate blade length, the process is usually composed of a few straightforward steps. Primarily it involves getting an accurate measurement of both the wheel diameter and the distance between the two wheels, often referred to as the ‘center-to-center distance’.

For an approximation, you could simply add double the wheel diameter to twice the center-to-center distance. However, this doesn’t take into account the depth of the wheel, which ‘shortens’ the blade riding on it. A more accurate method, includes the wheel’s radius in the calculation using the following equation: Blade Length= 2 * (Wheel’s Radius + Center-to-Center Distance).

But bandsaw manufacturers usually list the blade length in the product specifications for their saws. They work out these calculations, including all specifics like the wheel diameter, center-to-center distance, and any other necessary adjustments, such as the ‘tension range’ of the saw.

Sure, you can cut your raw blade stock down to the estimated size, but using an exact length from the manufacturer’s manual or specifications means the blade fits optimally. This leads to a smoother operation, improved performance, reduced wear on both your saw and blade, and ultimately, an overall safer working environment.

If a blade is too long, it might not fit on the bandsaw wheels, or it could problematically slip off while the saw is in operation. A blade that’s too short, on the other hand, could cause the bandsaw’s engine to stress or overheat, and it’s likely to break or snap from the excessive tension.

So there you have it – not just the ‘why’, but the ‘how’ in calculating bandsaw blade length. Of course, the golden rule is always to refer back to your bandsaw’s manufacturer guide or manual. More often than not, the specifics of your bandsaw are listed there. So, embrace the wisdom of the manual and truly get to know your tool of choice – your bandsaw will thank you for it!

Practical Application of Bandsaw Blade Calculation

The blade length is an integral part of the bandsaw operation, and understanding how to practically apply the blade length calculation is paramount. Unlike other parts of the bandsaw, this feature requires a more comprehensive understanding due to its influence on the tool’s overall performance and the final product’s quality.

Factors impacting blade length predominantly include wheel diameter and center-to-center distance. The size of the bandsaw’s wheels directly correlates with the blade’s length- larger wheels necessitate a longer blade to achieve perfect looping motion. At the same time, the center-to-center distance between the two wheels also determines the length of the blade to be used.

There are several ways to estimate the blade length. As a rule, one can employ the following formula: Blade length = (Wheel Diameter x Pi) x 2 + (Center-to-Center Distance x 2). Here, Pi is approximately 3.14, serving as a constant in this calculation. However, it’s worth mentioning that it serves as an approximation and the actual blade length may vary depending on specific bandsaw equipment.

For the most accurate measurement, one should follow the manufacturer’s determined blade length. This is typically specified in the bandsaw manual or guide and ensures the blade’s excellent fit to gain optimal performance.

Using a blade that is either too long or too short can lead to unnecessary hindrances during operation. Possible consequences consist of ineffective cuts, damaged work pieces, blade slippage, and even potential safety hazards.

When replacing the blade or maintaining the device, remember to refer to the bandsaw’s manufacturing guide. Not only is it an absolute wealth of information regarding the machine’s specifications, but it will also contain the necessary details about the bandsaw’s blade length.

In essence, the blade length’s practical application on a bandsaw is just as impactful as understanding the operational instructions.

Applying the correct blade length calculation ensures a seamless bandsaw operation and also provides a way to maintain and extend the tool’s lifespan, catapulting your craftsmanship onto a professional level. Happy sawing!

Even a robust piece of machinery like the bandsaw functions to its full potential only when calibrated accurately, which rests upon the owner’s keen comprehension of details, namely the blade length.

The very process of figuring this length is catalyzed, thanks to the availability of a proven mathematical formula. Through practical examples, we’ve seen how this equation assumes a key role in daily woodworking endeavors.

While it is evident that digesting these concepts may command some time, the endeavor means the difference between a misfit blade and a perfectly suitable one, hence, resulting in a direct impact on your project outcomes. As such, it pays to accrue this wealth of understanding in keeping the bandsaw hum at its prime.

![Laguna 1412 vs 14BX: Five Key Differences [Discovered] Laguna 1412 vs 14BX](https://woodpander.com/wp-content/uploads/2023/07/Laguna-1412-vs-14BX-A-Comprehensive-Comparison.jpg)