MDF is surely a bit different from other types of wood. You cannot treat them as solid wood. Hence, joining MDF at right angles is a big challenge.

Though the problem is common to almost all woodworkers, it is possible to join the medium-fiber boards maintaining the right angle. First of all, the entire joining process requires intensive attention. Also, you need to keep in the head a few things including proper sawing and using the right tools. However, knowing the proper joint technique and applying them wisely are the main keys. Moreover, MDF is totally different from boards made of solid wood. Also, it is surely the best material for building cabinets and other home decorating pieces.

Since you have already stepped on this site, let us guide you to the entire methods and related concepts. So, bear with us till the last of the article.

| Method | Strength | Difficulty | Tools Required | Cost |

|---|---|---|---|---|

| Butt Joint | Moderate | Easy | Clamps, Screws | Low |

| Pocket Hole | High | Moderate | Pocket Hole Jig, Screws | Moderate |

| Dowel Joint | High | Moderate | Doweling Jig, Dowels, Glue | Moderate |

| Biscuit Joint | High | Moderate | Biscuit Joiner, Biscuits, Glue | Moderate |

| Miter Joint | Low | Difficult | Miter Saw, Clamps, Screws | High |

One of our articles –How to Screw into MDF without Splitting?

What kind of joints are used to stick two pieces of MDF together?

Medium-density fiberboard (MDF) is an engineered material that includes small wood fibers. The fibers are basically glued with each other under compressed pressure and high temperature. Moreover, the manufacturers produce such material by pulverizing the wood into tiny fibers.

Certainly, MDF cores do not have strength like plywood or lumber. But when the pieces are joined together, you can use any type of joint. However, professionals suggest some joints that have helped them to maintain the right angles.

You can adopt different joining methods for MDF for example

- Dowels

These are cylindrical rods that woodworkers use to reinforce the joints of MDF pieces. Dowels can be very strong at times as when they are used to make joints, they take extensive force to break them apart. Dowels make a joint in one piece. Thus, to secure and strengthen the joint more, woodworkers further use an adhesive or wood glue.

- Pocket Holes

Like dowels, pocket holes also reflect their own strength while joining two MDF boards. However, the process is different from each other. Unlike dowels, the pocket holes joint method requires a recess to create in one MDF board and then conjunct the other board to it with screws.

Pocket holes are surely a great and popular joint option as it is appreciably resistant to any kind of vibration or accidental damage. Moreover, they can be easily assembled or disassembled.

- Butt joints

Butt joints are a great option if you want a simple joining of your MDF boards. Butt joints only require screws to make a connection. You can use specific metal fasteners for MDF as well. For reinforcing them, you can use dowels.

- Biscuit Joints

For alignment, biscuit joints on MDF work pretty well. They are nominally stronger. Also, biscuit joints on MDF are less susceptible to detrimental failure. However, there are possibilities that the biscuits may swell before the glue dries. Thus, you have to keep the fact in an account.

- Spline Joints

Spline joints offer a long-lasting and strong connection between MDF boards. You can also make decorative features of your furniture by following this joint method. However, selecting the right spline with the right thickness and width is important for joining MDF.

To have the right length of the spline, you can use a spline cutter jig. Also, this method requires cutting spline pieces at an angle of 45 degrees so that the connection becomes stronger as you assemble the pieces. However, while joining the splines to the board grooves at the right angle you can use a dowel jig.

- Dado Joints

This joint method is a good idea when you want to join plywood with an MDF. For that, create a dado in both plywood and MDF boards and then join them together. You can use a router to cut the dado.

- Rabbet Joints

Rabbet joints can also be an option for joining MDF. However, for cabinet construction, proceeding with this method will not be wise as the boards have less residual strength.

One of our articles –Building Furniture without Nails or Screws.

Joining MDF at Right Angles

Joining MDF End to End

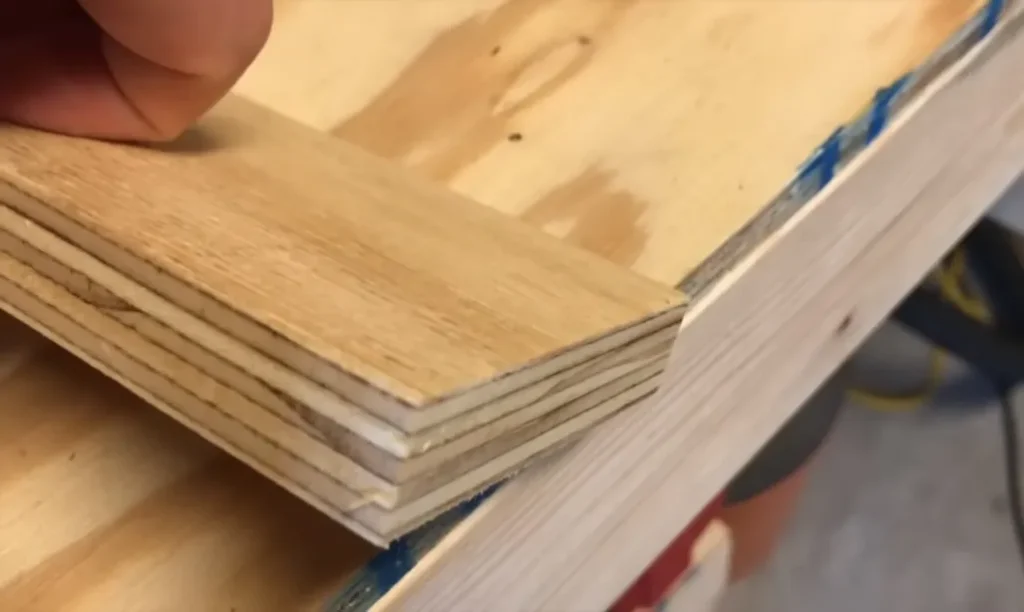

For having a right-angle end-to-end joining of MDF boards you can take the MDF boards and 8mm thick MDF strips. But if you want the joining to be stronger, then you can take 8mm thick plywood strips instead of MDF strips. It certainly shows a better result as plywood happens to be stronger than MDF material. Now, let’s get to the steps.

Step – 1: Cut Plywood Strips

As you already have the MDF boards, the first thing to do is cut plywood strips. You can cut strips having a 2 mm width from the 8 mm thick plywood strips. Cut as many strips as your project may require.

Step – 2: Secure the MDF Board

Now first make sure the MDF boards are cut at an angle of 90 degrees. It will ensure the boards are connected well.

Then secure the boards on your worktop with the help of a clamp. It will not allow the board to move while processing the next steps.

Step – 3: Make Channels on Boards

After securing the boards, make channels with a router. You can use a slotting cutter router bit. Make sure the machine bit is 31 with a diameter of 75 and cutting width and thickness of about 9.52 mm and 4.76 mm respectively.

Now rout on each face of the board. Make sure the channels are 8mm long. You may have to secure the board again while flipping the board upside down to make another pass on the other face of the board with the router.

However, make sure you are routing each slot 8mm thick so that the plywood strips can easily fit into the slots.

Step – 4: Fit the Strips to the Channels

After making the slots, apply adhesive to the plywood strips and routed channels. You need to glue each strip between the two MDF panels in the channels. Do not force the process as the fibers of the board may feel pressure and end up cracking. Also, forcing the process will not offer a right angle.

Step – 5: Join the Strips to the Boards

Now when both the MDF boards and plywood strips are ready for joining, apply adhesive on them. Make sure to apply adhesive, especially on the routed slots you have made in the MDF boards. Then adjust the position of the boards properly maintaining the alignment.

However, you may use a rubber mallet to hit the strips to insert them into the channels properly. A rubber mallet will create light hitting. Also, you need to be careful while hitting.

Step – 6: Join the Boards

Finally, apply adhesive and adjust the end-to-end of the MDF boards in a proper position so that they are aligned properly.

Then wait for the glue to dry properly until the next day. You will find the joint is invisible but the boards are joined correctly and at the right angle. Also, because of using plywood strips, you will have a stronger joint with no risk of cracking.

MDF Corner Joints

Even though corner joints are similar to edge joints, MDF corner joints can be done in two different ways. Let us describe each of them.

- Mitre Joint

To make corner joints invisible, you can use this method. Many people want the end edges of the MDF pieces to be less visible after joining them. To adopt this method, you need to saw your MDF boards in mitre first. It will make the joint less visible.

However, while mitre sawing, it is done diagonally from the end edges at an angle of 45 degrees so that the joint MDF panels then can be used at 90 degrees angle.

Now, it is time to join the mitred MDF boards. Professionals suggest using construction adhesive for the joining purpose as it will ensure the right angle.

- Angled Connection

It is one of the most common and simplest ways for MDF corner joints. Basically, it is a right-angle joint. Nonetheless, to adopt the method, first, you have to place and mount the MDF boards to each other at the right angles and then joined together. Making this angle connection of the boards is very easy.

However, unlike mitre joint, the right-angle joint does not ensure an invisible end. That means when the ends of two MDF panels join, you will see a visible end. Also, the ends look a bit unattractive compared to the boards’ top and bottom parts.

Screws for Joining MDF

MDF screws are specially made for joining MDF boards. However, while screwing, you have to be very careful as there are chances of splitting.

However, MDF screws are specially manufactured to avoid snapping or splitting of the thin board and its lower-density material.

They are made of stainless steel or brass. Also, they have slender shafts with sharp points for making the screwing process faster.

Nonetheless, you should not go for large screws. The screws should be at least 1 ¼ inch long. Again, for a 3/4 inches thick MDF board, professionals suggest using 2 inches-long screws with #3 or #2 Philips heads.

The length and thickness of the screws may vary depending on the thickness of the MDF board. However, you can go for some other types of screws like pan-head, flat-head, or oval-head screws. Use them with Phillips Drive.

It is better to make a pre-hole by using a drill machine if you want to use chipboard screws. However, MDF screws do not require predrilling. Again, try not to screw near the edges of the board. Otherwise, it will split. Moreover, adopting a countersink for screwing will make sure the MDF board surface is smooth.

Glues for Joining MDF

If you do not want to hurt the MDF material then you can simply use glue for joining two pieces. Gluing the boards will keep the surface smooth as always.

However, to join the ends together you must choose the right kind of glue. We have several options in hand like, wood glue, PVA glue, epoxy, or constructive adhesive. All these are considered strong glue.

However, you may not get your desired result using wood glue for joining MDF. Also, if you use other types of glue like the PVA one or the constructive adhesive, you have to ensure that you are applying plenty of it especially when joining mitred edges of MDF boards. Then again, too much glue on MDF can cause warping. So, be careful.

Sadly, glued board pieces will not support as much strength as screwed or nailed boards. Then again, if you use glue that is specially formulated for joining MDF pieces then you can get a great result. Therefore, make sure you are taking the right decision.

Nails for Joining MDF

Like MDF screws, you can also use MDF nails following the same methods. The nail has to have a very sharp point for use on MDF. Also, it should come with a thickness of more than 18-gauge.

You have to maintain the distance from the edges and corners while nailing. For your information, while nailing on the MDF board, make sure you are maintaining a distance of about 25 mm and 15 mm to the corner and edge respectively. Also, make sure to use nails with a small diameter.

Helpful Questions and Answers

What is the best method for joining MDF at right angles?

The best method for joining MDF at right angles depends on factors such as strength requirements and desired ease of assembly.

Can I use screws alone to join MDF at right angles?

Screws alone can be used to join MDF at right angles, but additional reinforcement may be needed for stronger joints.

Is glue alone strong enough for joining MDF at right angles?

Glue alone can provide sufficient strength for joining MDF at right angles, especially when used in conjunction with other methods.

Can I use pocket holes to join MDF at right angles?

Yes, pocket holes can be used to join MDF at right angles, providing a strong and relatively simple assembly method.

How to join two mdf boards lengthwise?

To join two MDF boards lengthwise, apply wood glue along the edges, align them precisely, and clamp securely until the glue dries completely for a strong bond. Additionally, reinforcing with screws from the underside can provide added stability.

How do you attach MDF to right angles?

You can attach MDF to right angles using wood glue and screws, ensuring a secure bond at the joint for stability and durability.

How do you join two MDF boards together?

To join two MDF boards together, you can use wood glue along the edges and clamp them tightly until the glue sets, ensuring a strong bond. Alternatively, you can reinforce the joint with screws or dowels for added stability.