Calculator tools can significantly simplify your shed-building project by helping you determine the exact amount of materials you need for framing, flooring, roofing, and siding.

Understanding your shed’s dimensions and the materials required not only ensures a sturdy structure but also helps you stay within your budget.

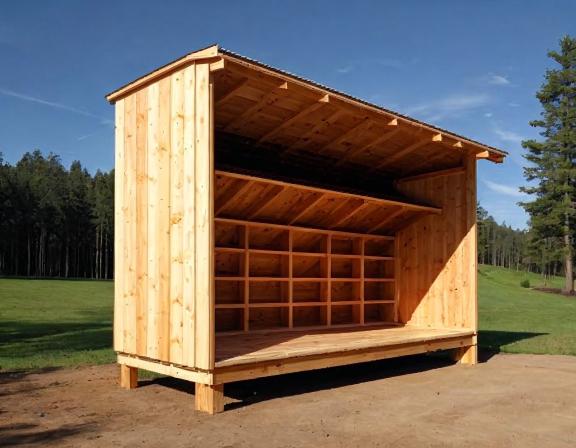

In this post, you will learn how to effectively utilize a wood shed material calculator to make informed decisions, so you can confidently create a durable and attractive outdoor storage solution tailored to your needs.

Wood Shed Material Calculator

Understanding the Importance of Material Selection for Wood Sheds

To build a wood shed that meets your practical needs and withstands the test of time, understanding material selection is crucial.

The right materials not only enhance the shed’s overall durability and functionality but also contribute to its aesthetic value and environmental impact.

Choosing quality materials ensures your investment lasts, making your outdoor storage space both reliable and visually appealing.

The Role of Material in Structural Integrity

Material selection is necessary for maintaining the structural integrity of your wood shed.

The type of wood you choose dictates how well your shed can withstand various forces, such as wind and weight from stored items.

For example, opting for strong framing like 2×4 or 2×6 lumber can significantly enhance the overall sturdiness of your structure.

Environmental Impact of Material Choices

Impact is a vital consideration when selecting materials for your shed. Wood sourced sustainably or treated with eco-friendly processes minimizes environmental harm. Using materials that are readily renewable, such as responsibly harvested lumber, supports a healthier ecosystem.

Role of sustainable materials goes beyond compliance; it reflects your commitment to environmental stewardship. For instance, choosing pressure-treated lumber can extend the life of your shed while ensuring it can withstand moisture and pests, ultimately reducing the need for frequent replacements. This not only conserves resources but also decreases landfill waste.

Enhancing Aesthetics Through Material Selection

The materials you choose for your wood shed directly influence its visual appeal. Traditional wood options like cedar provide a classic look, blending seamlessly with your outdoor environment, while vinyl siding offers a clean, modern finish. The right combination can turn a utilitarian structure into a charming feature of your yard.

Sheds with thoughtfully selected materials not only meet functional requirements but also showcase your personal style.

From the beautiful grain of cedar to the sleek finish of vinyl, the choices you make reflect your taste and can elevate your outdoor space. When building, consider how different materials will affect the overall aesthetic to ensure your shed enhances your property’s appeal.

Essential Factors to Consider in Wood Shed Construction

Assuming you are begining on the exciting journey of building your own wood shed, there are several necessary factors to consider that will influence the durability, functionality, and overall success of your project. These factors include:

- Climate and Weather Considerations

- Budgeting for Materials and Labor

- Purpose and Function of the Shed

Thou shall take the time to evaluate these key elements to ensure a successful shed construction.

Climate and Weather Considerations

Factors such as temperature fluctuations, precipitation, and wind conditions play a significant role in determining the materials you choose.

In regions with harsh winters or heavy rainfall, you must select weather-resistant materials like cedar or pressure-treated lumber to ensure your shed can withstand the elements over time.

Budgeting for Materials and Labor

Any successful project begins with a clear budget. You need to calculate the costs of materials and labor accurately to avoid overspending. Factors like the type of wood, size of the shed, and additional features such as windows or insulation will determine your overall expenses.

Considerations for budgeting include not only the upfront costs of materials but also potential long-term expenses. For instance, while cedar is more expensive initially, its durability can save you money in maintenance and replacement costs down the line.

Additionally, including labor costs, whether you hire help or plan to do it yourself, will provide a clearer financial picture.

Purpose and Function of the Shed

Weather can greatly impact the purpose and functionality of your shed. Identify what you plan to use your shed for—be it storage, a workshop, or a garden potting area—to determine the necessary features, insulation, and layout to accommodate those needs effectively.

Materials you select should align with the intended use of your shed. For example, if you are storing gardening equipment and tools, proper ventilation and insulation are necessary.

A well-thought-out purpose will inform your construction choices, ensuring your shed serves you well for years to come.

Common Wood Types: An Overview

All wood types have unique characteristics that can significantly impact the durability, aesthetics, and overall performance of your shed. Understanding these differences helps you make informed decisions on which materials to use for your project.

- Cedar: Naturally resistant to rot and insects.

- Pressure-Treated Lumber: Affordable and chemically treated for weather resistance.

- Redwood: Attractive and durable, with natural decay resistance.

- Pine: Cost-effective and easy to work with, though not as durable.

- Spruce: Good strength-to-weight ratio and relatively inexpensive.

Assume that your choice of wood will greatly influence how well your shed withstands the elements and serves your storage needs.

| Wood Type | Characteristics |

|---|---|

| Cedar | Rot-resistant, durable, and aesthetically pleasing. |

| Pressure-Treated Lumber | Long-lasting, moisture-resistant, and affordable. |

| Redwood | Visually appealing and resistant to decay, but pricier. |

| Pine | Softwood that is easy to work with but less durable. |

| Spruce | Lightweight and strong, often used in construction. |

Characteristics of Different Woods

Different woods offer various advantages depending on your needs. For instance, cedar is known for its natural resistance to rot and insects, making it ideal for outdoor use.

Pressure-treated lumber, on the other hand, is a budget-friendly option that provides long-term durability by protecting against moisture and pests.

Comparing Hardwoods vs. Softwoods

Wood types can generally be categorized as hardwoods and softwoods, each with distinct properties that affect their suitability for shed construction.

| Type | Features |

|---|---|

| Hardwoods | Dense, durable, and often more expensive. |

| Softwoods | Lightweight, easier to work with, and more affordable. |

Common hardwoods include oak and maple, which are valued for their strength and longevity, making them suitable for structural elements in sheds. Softwoods like pine and spruce are appropriate for framing and siding, as they provide an economical option while still being reliable for less demanding roles.

Sustainability of Wood Sources

To ensure the longevity of your project, consider the sustainability of the wood you choose. Sustainably sourced wood minimizes environmental impact while supporting responsible forestry practices.

With a growing emphasis on sustainability, selecting wood from certified sources can significantly reduce your ecological footprint. Look for certifications such as the Forest Stewardship Council (FSC) to ensure that your materials are sourced responsibly, contributing to healthier forest ecosystems and improved sustainability practices in woodworking.

Wood Shed Framing Techniques

Once again, the framing of your wood shed is a critical element that sets the foundation for a robust and durable structure. Understanding the different framing techniques will ensure that your shed can withstand the elements while meeting your storage needs.

Types of Framing Methods

Framing methods vary based on design preferences and specific use cases. Here are some common types:

- Balloon Framing: Uses vertical studs that extend from the foundation to the roof.

- Platform Framing: Each floor or level is built separately, allowing for faster construction.

- Timber Framing: Involves large wooden beams for a strong aesthetic and structural appeal.

- Post and Beam: Uses columns and beams to create a sturdy framework, enhancing open space.

- Light Frame: Utilizes smaller wooden sections for a lighter, cost-effective build.

Thou must choose the method that aligns with your skills and budget.

| Framing Method | Benefits |

| Balloon Framing | Good for tall structures and strong walls. |

| Platform Framing | Ideal for small projects and easier to construct. |

| Timber Framing | Offers aesthetic appeal and durable strength. |

| Post and Beam | Allows for spacious interior layouts; great for sheds. |

| Light Frame | Cost-effective and uses less wood material. |

Importance of Proper Framing for Longevity

Proper framing ensures your shed withstands harsh weather and supports its weight over time.

Understanding the importance of proper framing cannot be overstated. It not only affects the structural integrity of your shed but also influences the longevity of materials used. With good framing, your shed resists elements like heavy rain, snow, and wind that could compromise its stability.

Investing time in proper framing techniques will save you money in repairs and prolong the life of your shed, enhancing your outdoor space for many years.

Tools and Equipment for Framing

Shed framing requires specific tools and equipment to ensure precision and durability during construction.

This includes items like a level, framing square, circular saw, and power drill. You’ll also need safety gear such as goggles and gloves.

Utilizing the right tools not only helps you achieve accurate measurements but also streamlines your building process, making it easier for you to create a high-quality frame. Additionally, understanding how to use these tools effectively can improve your overall efficiency and the final outcome of your shed project.

Choosing the Right Foundation for Your Wood Shed

Many factors contribute to the structural integrity of your wood shed, and selecting the right foundation is one of the most critical steps. A solid foundation protects your shed from moisture and ground movement, ensuring that it stands the test of time.

Types of Foundations (Concrete, Gravel, etc.)

Any good foundation choice will provide a stable base for your shed. Here are some common foundation types:

| Foundation Type | Description |

| Concrete Slab | A durable and solid base that offers great support. |

| Gravel Pad | A cost-effective and well-drained option. |

| Concrete Blocks | Versatile and allows for easy leveling. |

| Piers and Beams | Elevates your shed, providing airflow and moisture protection. |

| Wood Skids | Easy to install but less durable in wetter climates. |

Thou should choose your foundation type based on your climate, shed size, and budget to ensure optimal stability and longevity.

Impact of Foundation Type on Shed Durability

Durability is significantly influenced by the foundation type you choose. Each type has unique benefits and drawbacks that can affect your shed’s performance over time.

It is vital to understand that a well-chosen foundation can prevent issues like rot, shifting, and settling. For instance, concrete provides superior longevity and stability, while gravel allows for drainage, which is critical in wet climates. Selecting the right foundation helps your shed endure harsh weather conditions, enhancing its lifespan overall.

Preparing the Ground for Your Shed Foundation

Ground preparation is a crucial step before laying your shed foundation. Properly preparing the ground ensures a level, stable surface, which is fundamental for your shed’s overall stability.

Right ground preparation involves clearing vegetation, leveling the site, and compacting the soil. A well-prepared base minimizes the risk of moisture issues and structural problems down the road. Taking the time to ensure your foundation area is ready will lead to a more robust and durable wood shed.

Structural Components of a Wood Shed

After determining your wood shed’s size and style, understanding its structural components is crucial for ensuring durability and stability. The shed’s walls, insulation, joists, and rafters play significant roles in creating a robust structure that can withstand various weather conditions and maintain functionality over time.

Overview of Shed Walls and Insulation

Shed walls are crucial for providing support and protection against the elements. Insulation within the walls is equally important, as it helps regulate temperature and enhances energy efficiency.

By selecting effective insulation materials, you can create a comfortable space that stays cool in summer and warm in winter, making your shed more than just a storage unit.

Importance of Joists and Rafters

Structural joists and rafters are key components that help support the roof and floor of your shed. They distribute weight evenly and provide crucial stability, ensuring that your shed maintains its structural integrity over time.

This stability is vital, especially when considering the weight of stored items and the potential impact of snow or rain buildup on the roof. Using appropriate materials like 2×6 or 2×8 joists spaced 16 inches apart will enhance the load-bearing capacity, making your shed a safe storage solution for various tools and equipment.

Choosing the Appropriate Width and Spacing

Any shed project requires careful consideration of the width and spacing of the joists and rafters to ensure adequate support and durability. When properly spaced, they help distribute the weight effectively, minimizing the risk of sagging or structural failure.

Rafters should typically be spaced 24 inches apart to provide a strong framework for the roof. By choosing the right dimensions, you can optimize your shed’s overall strength and ensure it can withstand environmental stresses while keeping your stored items secure and safe.

Roofing Materials for Wood Sheds

Roofing is an vital aspect of constructing your wood shed, as the right materials can significantly impact its durability and aesthetics. Understanding the available options will help you make a well-informed decision that best fits your needs and style preferences.

Types of Roofing (Metal, Shingles, etc.)

For shed roofing, several materials are ideal, each with unique benefits. Metal roofing offers durability and a modern look, while asphalt shingles are popular due to their affordability and ease of installation. Below is a comparison of common roofing materials:

| Type | Advantages |

|---|---|

| Metal | Long-lasting and lightweight |

| Asphalt Shingles | Cost-effective and versatile |

| Wood Shingles | Natural appearance and insulation properties |

| Slate | Highly durable and attractive |

| Tile | Weather-resistant and energy-efficient |

Any of these options can make a fantastic roofing choice depending on your environment and personal aesthetics.

Best Practices for Roof Installation

Metal roofing is a great choice for your shed; however, proper installation is key to maximizing its lifespan and effectiveness. Ensure the roof is correctly pitched to facilitate proper drainage and prevent water pooling, which can lead to leaks and damage.

Wood materials should be cut precisely, with adequate overlaps to ensure seamless integration at the seams. It’s crucial to use high-quality fasteners that are suitable for the type of metal roofing you’re applying. Regular inspection and maintenance will also prolong the life of your roofing materials.

Benefits of Adequate Roofing Ventilation

An adequately ventilated roof is vital for maintaining your shed’s structure and contents. Proper ventilation helps regulate temperature and moisture levels, preventing mold growth and extending the lifespan of your roofing materials.

In addition, maintaining air circulation can help mitigate the heat buildup during summer months, keeping your shed cooler and more comfortable for any stored items. Consider installing roof vents or gable vents to ensure airflow and enhance the shed’s overall efficiency.

Materials chosen for ventilation should complement your roofing system while allowing for easy installation. Ensuring adequate ventilation in your shed is a straightforward step that pays off in significant long-term benefits for your structure’s integrity and usage.

Material Selection for Shed Flooring

Unlike many aspects of shed construction, the choice of flooring materials can significantly impact both the longevity and functionality of your shed. Selecting the right flooring not only enhances the aesthetics but also ensures a strong and durable base for your stored items.

Different Flooring Options (Wood, Composite, etc.)

On the market, you can find various flooring options for your shed, including traditional wood planks, composite materials, and even Oriented Strand Board (OSB). Wood like cedar offers natural resistance to rot, while composite materials provide durability with lower maintenance needs, allowing you to choose based on your budget and preferences.

Structural Considerations for Shed Floors

Material selection for your shed’s floor is critical from a structural standpoint, as it needs to support the weight of the shed itself and any items you plan to store. Considerations include the thickness of the boards and spacing between joists to ensure stability.

Wood flooring should ideally be at least 3/4 inch thick for sturdiness, while joists spaced 16 inches apart will provide sufficient support. Using 2×6 or 2×8 timber for joists ensures that your floor can handle heavy loads, making it a reliable choice for long-lasting performance in your shed.

Maintenance and Longevity of Floor Materials

Materials you choose for your shed’s flooring can greatly affect both your maintenance efforts and the lifespan of the floor. Opting for lower-maintenance solutions can save you time and costs in the long run.

Understanding how to protect your flooring is necessary; wood materials may require regular sealing to fend off moisture and pests, while OSB offers more resilience and requires less upkeep. By investing in quality materials and proper maintenance, you can maximize the longevity of your shed’s floor, ensuring it remains functional and visually appealing for years to come.

Siding Options for Exterior Protection

Keep in mind that the siding you choose is crucial for protecting your shed from the elements and enhancing its appearance. Various options are available, each with unique advantages.

Comparing Wood, Vinyl, and Metal Siding

To help you make an informed decision, here’s a quick comparison of popular siding materials:

| Material | Pros |

| Wood | Timeless appeal, customizable, natural insulation |

| Vinyl | Low maintenance, durable, weather-resistant |

| Metal | Fire-resistant, long-lasting, modern look |

Aesthetic Considerations for Your Shed

An appealing exterior can significantly enhance the overall look of your shed and complement your outdoor space. When choosing siding, consider colors, textures, and styles that harmonize with your home and garden.

A striking visual appearance not only improves the aesthetic value of your shed but can also increase your property’s curb appeal. Think about incorporating decorative elements or contrasting colors to make your shed a standout feature in your yard.

Weatherproofing Techniques for Siding

Considerations for weatherproofing your siding are necessary to prolonging your shed’s lifespan and maintaining its functionality. Proper installation and maintenance are key to ensuring your siding withstands harsh weather conditions.

With the right weatherproofing techniques, such as sealing joints and applying protective coatings, you can significantly enhance the durability of your chosen siding material. This will help prevent leaks, reduce maintenance needs, and keep your shed looking great for years to come.

Insulation Choices for Temperature Regulation

Now, keeping your shed comfortable year-round is important, especially if you store temperature-sensitive items or plan to use the space as a workshop. Selecting the right insulation can significantly enhance your shed’s energy efficiency. Below are some effective insulation options to consider:

| Insulation Type | Description |

| Fiberglass | Made from fine glass fibers, it traps air and prevents heat transfer, providing excellent thermal performance. |

| Foam Board | A rigid insulation material that offers high insulating values with less thickness, great for tight spaces. |

| Reflective Insulation | Utilizes reflective materials to divert radiant heat, ideal for sheds exposed to direct sunlight. |

Benefits of Insulation in a Shed

Insulation not only enhances your shed’s comfort by keeping temperatures steady but also protects your belongings from extreme weather conditions. It reduces energy costs by minimizing the need for heating and cooling, making your shed more energy-efficient and cost-effective over time.

Comparing Fiberglass, Foam, and Reflective Insulation

To help you choose the best insulation for your shed, consider the following comparison:

| Insulation Type | Advantages |

| Fiberglass | Cost-effective, efficient, easy to install, and widely available. |

| Foam Board | High insulation values for minimal space, lightweight and moisture-resistant. |

| Reflective Insulation | Reduces heat gain in hot climates, easy to install over existing materials. |

Reflective insulation works by reflecting radiant heat away, making it particularly valuable for sheds in sunny locations. Foam board provides excellent thermal resistance in a compact form, while fiberglass is the budget-friendly option with good overall performance. Each type has distinct features that suit various needs and climates, allowing you to tailor your insulation choice to your specific requirements.

How to Properly Install Insulation

Temperature control in your shed starts with proper insulation installation. Ensuring a snug fit in cavities is crucial to prevent heat loss and maximize efficiency. Use appropriate sealing to eliminate gaps that can compromise insulation effectiveness.

A proper installation begins with measuring your shed and choosing the right insulation type based on space and climate. Make sure to cover walls, ceilings, and floors, and use vapor barriers as needed to enhance moisture resistance. Properly installed insulation will not only improve comfort but also extend the lifespan of your shed’s structure and contents.

Importance of Ventilation in Sheds

Not only does proper ventilation ensure your shed remains a functional space, but it also extends its lifespan by preventing moisture buildup and reducing heat.

It’s crucial for safeguarding your tools and materials against rust and decay. With the right ventilation system, your shed can maintain a comfortable environment, making it an effective storage solution.

Types of Ventilation Systems

One of the best ways to achieve proper ventilation in your shed is by incorporating a mix of passive and active systems. Here’s a breakdown of common ventilation types:

- Static vents – Simple, fixed vents that allow air exchange.

- Ridge vents – Installed along the shed’s peak, promoting airflow.

- Roof vents – Openings at the roof slope that help expel hot air.

- Window vents – Depending on your usage, opening windows can enhance airflow.

- Powered fans – Active ventilation systems that can be installed for more significant airflow control.

This ensures that air circulates effectively, keeping your shed dry and comfortable.

Benefits of Proper Ventilation

Sheds that are properly ventilated experience lower humidity levels, protecting your stored items from moisture-related damage. Additionally, ventilation prevents heat accumulation, making it a suitable workspace, especially in summer.

Proper ventilation controls the temperatures inside your shed, allowing you to store items safely, especially those sensitive to temperature changes.

Furthermore, it reduces the risk of mold and mildew, ensuring the overall integrity of your shed and its contents. This not only helps in achieving a healthier environment but also reduces maintenance costs in the long run.

Installation Tips for Ventilation

Any shed ventilation plan should be carefully executed to maximize efficiency. Keep the following tips in mind during installation:

- Select vent locations that allow cross-ventilation.

- Ensure vents are elevated to promote airflow.

- Install at least two openings for optimal air movement.

- Consider the direction of prevailing winds.

- Do regular maintenance to keep vents clear.

This attention to detail will help maintain an ideal environment within your shed.

Ventilation systems should be tailored to your shed’s specific needs, taking into account its size and intended use. By assessing factors such as airflow direction and vent placement, you can achieve a comfortable environment that prevents moisture buildup and maintains your shed’s durability. This proactive approach not only protects your investments but also promotes a healthy workspace.

Calculating Material Needs

Your ability to accurately estimate the materials required for your wood shed project is necessary for ensuring its durability and cost-effectiveness.

Proper calculations help you avoid over- or under-purchasing, saving both time and money.

This chapter will guide you on utilizing a wood shed material calculator, understanding how to quantify materials based on your shed size, and accounting for waste and overages to achieve a successful DIY project.

Using a Wood Shed Material Calculator

Shed material calculators are handy tools that streamline the calculation process for your wood shed project.

By entering dimensions such as wall area, floor area, and roof area, you can quickly determine the amounts of various materials needed. This ensures you have sufficient materials on hand while optimizing your budget and minimizing waste.

Quantifying Materials Based on Shed Size

With the right shed size as a foundation, you can effectively quantify the necessary materials. Start by measuring the wall, floor, and roof areas of your shed. The material calculator converts these dimensions into specific quantities of wood, siding, insulation, and more, tailoring the project to your unique needs.

Calculator tools give you exact figures based on the dimensions of your shed. By understanding the wall area, floor area, and roof area, you can accurately estimate how many boards for framing, siding, and roofing materials are required.

For example, if your shed has a wall area of 200 sq ft, a floor area of 150 sq ft, and a roof area of 250 sq ft, a material calculator will help translate these areas into precise quantities of lumber and other materials needed for construction.

Accounting for Waste and Overages

Calculating materials is necessary, but accounting for waste and overages is equally important. It’s wise to factor in about 10% more material than the calculator suggests to accommodate errors, cuts, and any unforeseen mishaps during construction. This small cushion can save you from inconvenient trips to the store mid-project.

A good rule of thumb is to add an additional 10% to your calculated materials to cover waste and potential overages. When working with materials like wood, you may encounter knots or imperfections that render some pieces unusable.

This buffer not only alleviates stress during your build but also ensures continuity in material availability, keeping your project on track without major delays.

Cost Analysis and Budgeting Strategies

Despite the excitement of building your own wood shed, understanding the costs involved is crucial for a successful project.

A detailed cost analysis helps you stay within your budget while ensuring you choose the right materials for durability and aesthetics.

Estimating the Total Cost of Shed Construction

To accurately estimate the total cost of your shed construction, begin by calculating the material quantities needed for framing, flooring, roofing, and siding.

Use the measurements from your wood shed material calculator to determine the areas and then research current prices for each material. Don’t forget to include additional costs like tools, permits, and labor if necessary.

Balancing Quality and Affordability

Affordability is crucial when choosing materials for your shed, but it shouldn’t compromise quality. Strong and durable wood types like cedar and pressure-treated lumber may have higher upfront costs but offer significant savings over time through reduced maintenance and longevity.

Consider making a balanced choice that meets your budgetary constraints while ensuring your shed will stand the test of time.

Strategies for balancing quality and affordability include prioritizing critical structural elements where durability is crucial, such as the foundation and roofing materials, while considering more cost-effective options for non-load bearing components.

Research bulk purchasing options and local suppliers to find materials that offer the best value without sacrificing quality. Ultimately, investing intelligently will yield a wood shed that lasts and meets your needs.

Tips for Reducing Material Costs

One way to reduce material costs is by shopping smart and planning ahead. Look for sales, bulk pricing discounts, and local suppliers who may offer better deals than big-box retailers. You can also consider using reclaimed wood for certain parts of your shed, which can save money while providing unique character.

Additional tips for reducing material costs include:

- Reassess your design to simplify construction and reduce waste.

- Utilize free online resources and converters for estimating material needs accurately.

- Join local DIY groups to share tools and experiences.

Assume that every little saving adds up, and keeping an eye on potential reductions can significantly impact your overall budget.

A final aspect of minimizing costs involves evaluating alternative materials that offer similar benefits at a lower price point. For instance, consider using engineered wood products or OSB for structural elements instead of solid wood, as they can provide significant savings while still being durable.

Include these strategies in your planning:

- Periodically review your budget to make adjustments as necessary.

- Plan for potential overruns or unexpected costs to avoid surprises.

- Network with local builders to gain insights and potential deals.

Assume that each practical approach to reducing material costs can enhance your shed-building experience while maintaining quality and functionality.

Final Words

From above, you have gained valuable insights into selecting the best materials for your wood shed. By understanding the various wood types, roofing, flooring, siding, and insulation options, you can make informed decisions that will enhance the durability and aesthetic appeal of your shed.

Utilizing a wood shed material calculator allows you to accurately estimate your material needs, ensuring a successful DIY project that meets your storage requirements while improving your outdoor space.